our technologies

Plastic injection moulding

Pouring hotmelt

Overmoulding of elastomers

Pouring out two-component adhesive

Hard plastic spraying and high-pressure spraying processes

In-house tool design and construction

Manufacture of own production lines including tools

EDM machines, CNC milling machines, lathes, industrial 3D printing

an experienced team of 20 employees in the department

Development / manufacture of own production lines

Planning: Inventor software

Individual production lines; product-specific specialisation for the production of single-colour lines only

Test jig construction

Wear parts production

Special machine engineering

IDC technology with special systems

Stocko – semi-automatic and fully automatic in combination with Komax fully automatic machines

Lumberg – Semi-Automatic machine

Erni – – Semi-Automatic machine

Test tables for 100% electrical function control

Test: Electrical continuity, short circuit, polarity reversal test, latching check, checking of seals, leakage test, checking of armature and cable tie, contour checking of codings, checking of secondary locking and catch mechanism.

Marking of products with DataMatrix code (DMC)

Laser and inkjet printing with 100% camera inspection

Ultrasonic welding / parallel joints

Parallel connectors and compacts End wire

Efficiency despite manual work

Production

State-of-the-art machines and optimised production chains guarantee efficient and process-reliable manufacturing. Downtimes can be prevented through constant new investments and interval-based maintenance.

Our greatest asset is our experienced staff. These are used wherever automated, machine-based production reaches its limits. That is why we count on long-term working relationships with trained employees in order to guarantee the high quality standard.

With our own specially developed test tables, an electrical function check is already made during production, which eliminates any faults by 100%.

Perfect symbiosis between automation and manual labour

Proven quality

Laboratory tests

Logistics

In order to be able to react independently and flexibly to all situations, we maintain our own truck fleet. Thanks to our well-positioned production facilities and the constant exchange of goods between the individual locations, we are able to keep delivery times to Central and Eastern Europe very short. The transport takes place directly from the nearest high rack warehouse.

For smooth integration with your merchandise management system, we work with EDI and ASN data exchange, as well as interfaces to various ERP systems such as SAP.

proven quality standard

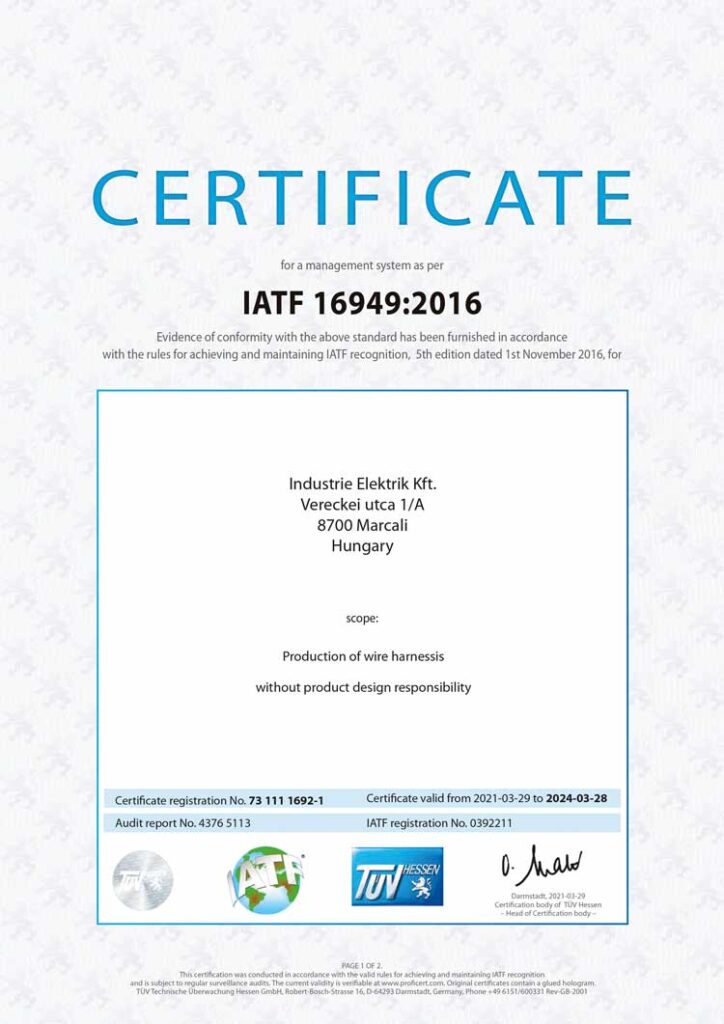

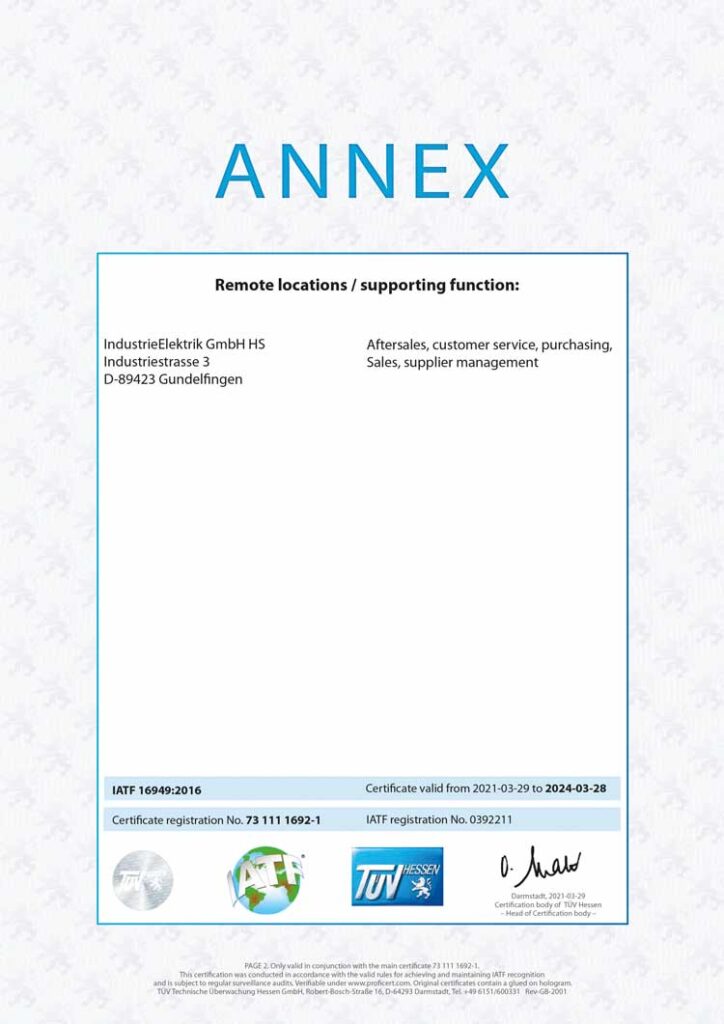

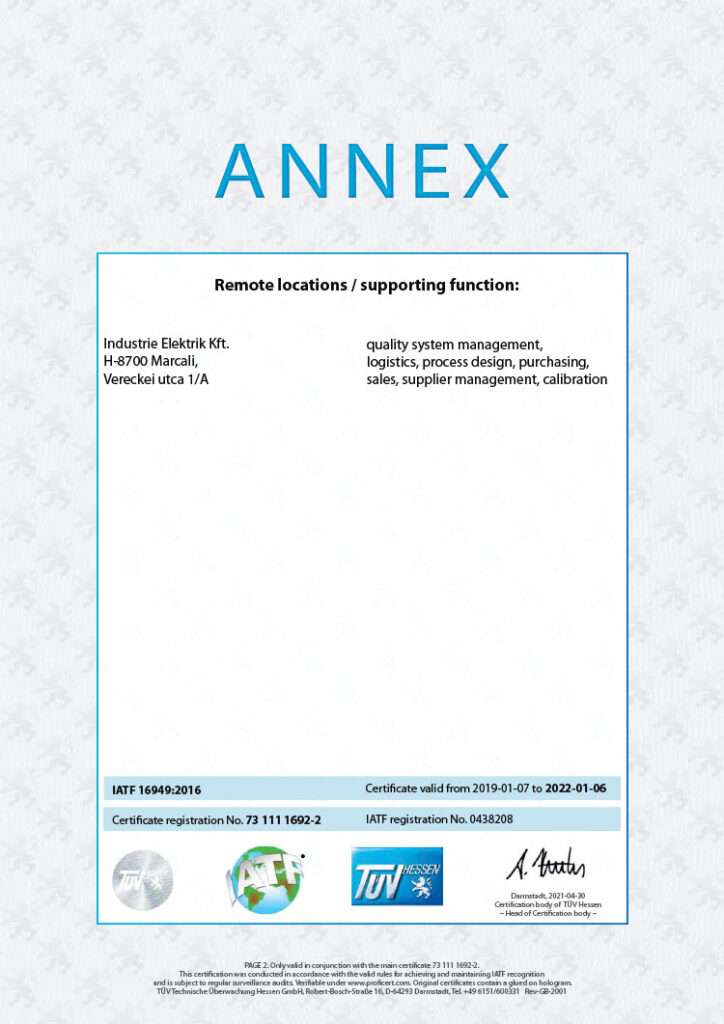

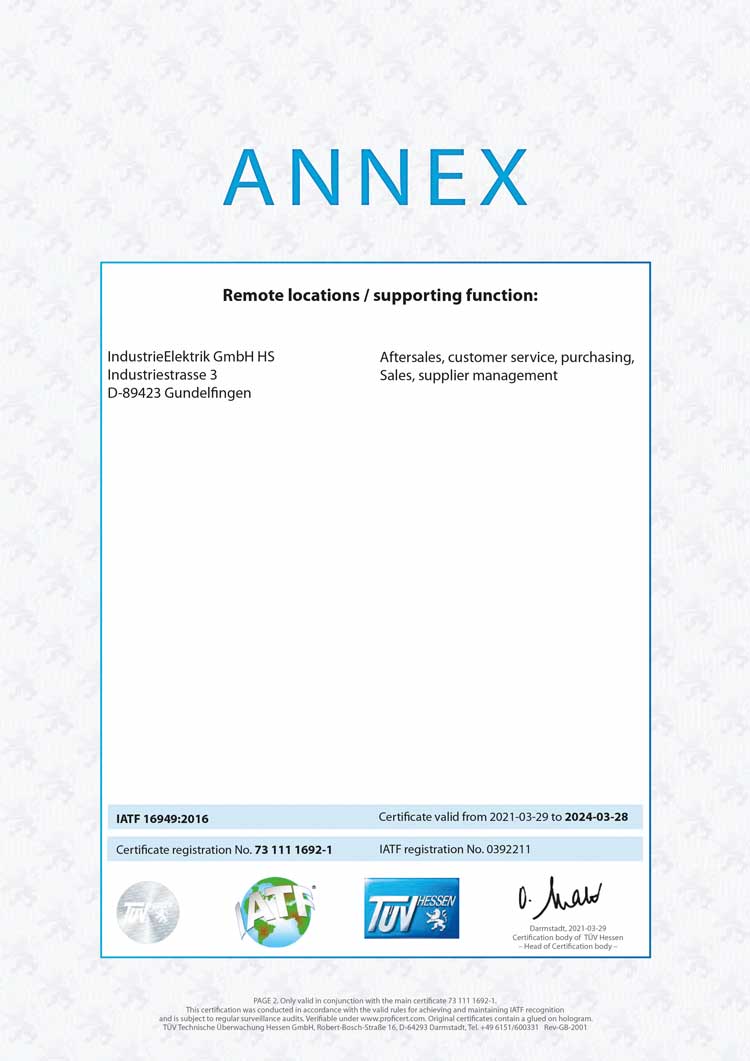

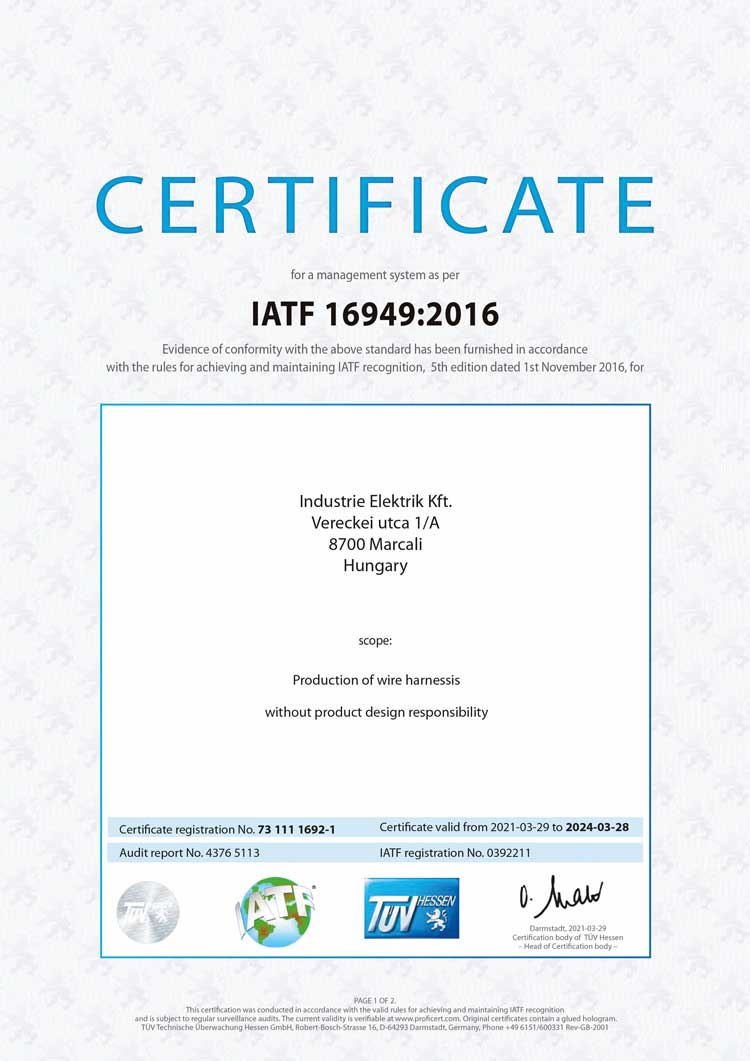

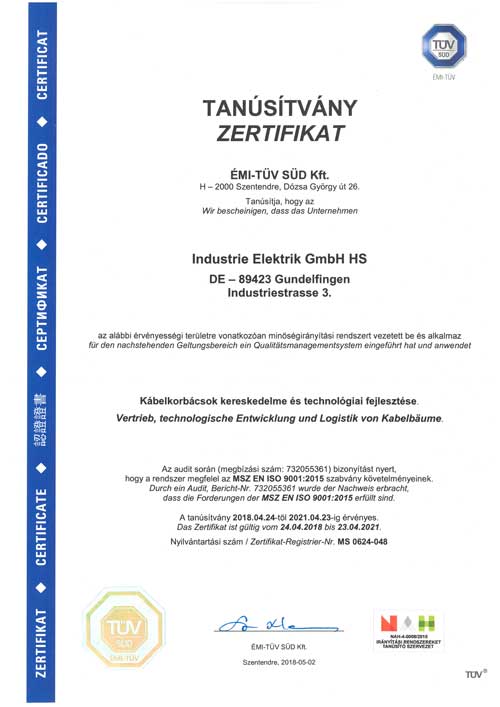

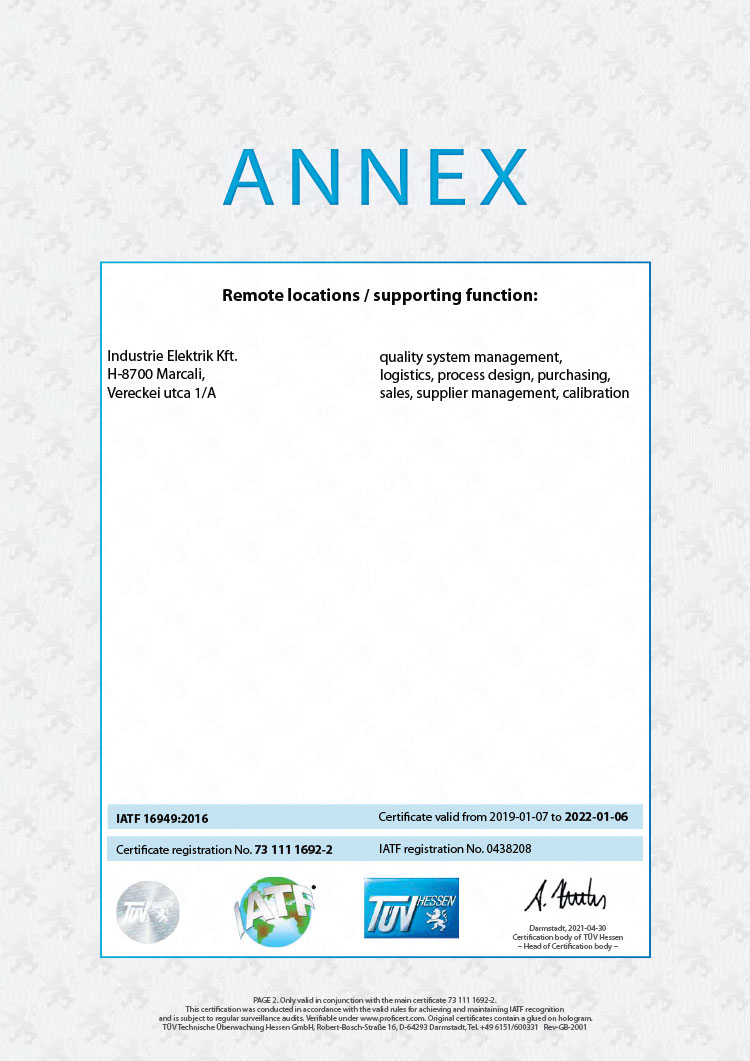

IATF and TUV certificates

As a certified company, we continuously set ourselves high quality and service requirements. All company divisions certified by TUV-Sued according to IATF 16949:2016.

Accordingly, transparent processes, documented test procedures and constant maintenance of orders as well as continuous further development of our quality management are a matter of course.